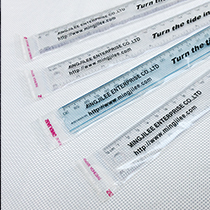

- Manufacturing of the packing system for ruller is fully automatic, from material feeding → ultrasonic dotting → hanging hole punching → packed product feeding → heat side sealing to become the packed product.

- Each unwinding device is equipped with the edge position controller to make sure the position of the feed material remains precise.

- This machine is equipped with various precision and durable punching molds with a very low breakdown rate, connecting to the servo motor and digital computing unit for length control to allow a very precise punching position.

Auto. Ruler Feeding and Packing Machine

MGA-68C-400

Features

Specifications

swipe your finger

| Model | MGA-68C-400 | |

| Wrap material | PE, PP, BOPP | |

| Ruler packing size | 311 (L) × 35 (W) × 3 (H) mm | |

| Output | 14 - 20 pcs/min | |

| Machine dimensions | 5,100 (L) x 2,100 (W) x 1,700 (H) mm | |

| Machine weight | 1,750 kg | |

| Required power | 4.5 kw | |

| Optional equipment | (1) Adhesive tape unwinding device : 1 | |

| Remarks | As we continuously keep working on research and improvement, we preserve the right to change all of the specifications, design and characteristics on this catalogue without notice. | |