- This unit designed especially for all kinds of data pocket: from material intending to finished product, It may be completed on production line which will save labor cost and increase production capacity.

- This unit uses special synchronous cutting and sealing to enable the size of the data bag on production to be of uniform, the sealing is neat and clean, and reduce the waste material to the minimum.

- This unit may choose to use all kinds of precision and durable punching mold with very low breakdown rate, and may match punching sensor movement to make precise punching position which is uneasy to run off.

- This unit uses high quality, high performance parts to incorporate with all kinds of control and monitor systems.

- This sealing equipment is of special design which may enable the data packet to be in different specifications and types, the purpose of application covers a wide range.

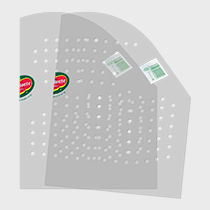

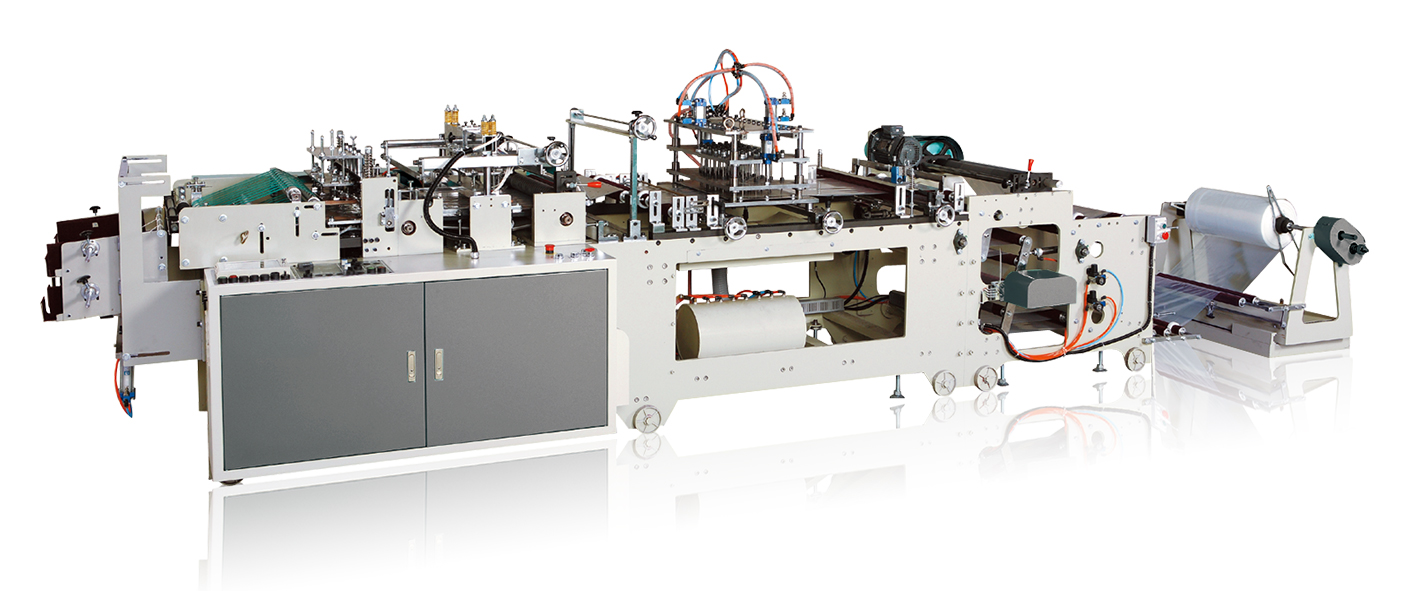

Banana Bag Making Machine

MGA-17B-700SP

Features

Specifications

swipe your finger

| Model | MGA-17B-700SP | |

|

Feed material |

P.P. / P.E. blown film | |

| Effective cutting width | 250 - 600 mm | |

| Effective cutting (feeding) length | 150 - 550 mm | |

| Single layer film thickness | 0.03 - 0.12 mm | |

| Output | 40 -120 pcs/min | |

| Machine dimension | 7,000 (L) × 1,700 (W) × 1,900 (H) mm | |

| Machine weight | 3,200 kg | |

| Required power | 3.7 kw | |

| Optional equipment |

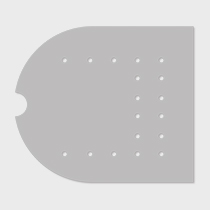

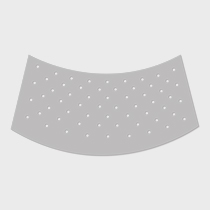

(1) Electronic E.P.C : 1 (2) 3'' unwinding air shaft : 1 (3) The complete part heat sealing mold : 1 (4) ψ6mm precision punching mold (holes quantity: 20 - 38 holes) : 1 (5) ψ6mm precision punching mold (holes quantity: 85 - 120 holes) : 1 (6) Arc-shaped banana bag production : 1 (7) Non-woven banana bag production : 1 |

|

| Remarks | As we continuously keep working on research and improvement, we preserve the right to change all of the specifications, design and characteristics on this catalogue without notice. | |