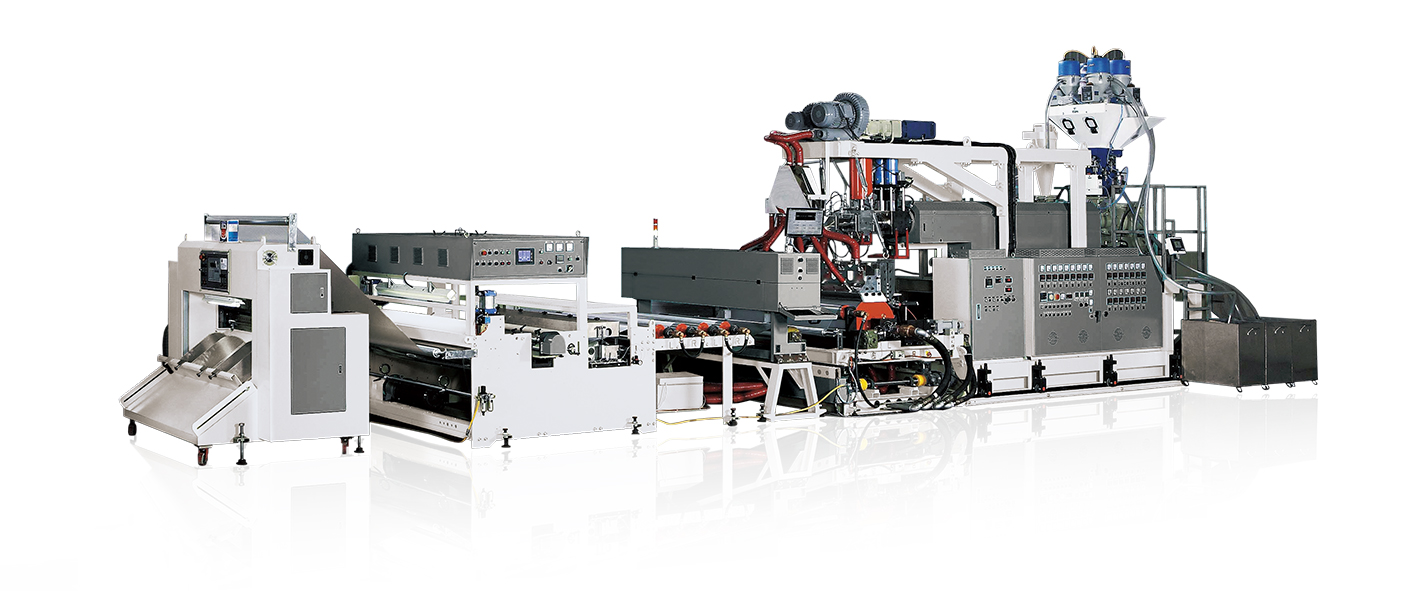

- Stand of extruding unit can be movable forward and backward which will increase convenience on controlling.

- Screw is special mixing function and hi-plasticizing capability design, it incorporates with European imported static mixer to ensure melting of resins, homogeneous color and increase on extruding output.

- T-die is special double throttling design to enable adjustment for sheet thickness to be more accurate.

- Temperature control uses SCR system, tolerance of temperature for that is±1℃, this may precisely control plasticizing processes, sheet thickness, flatness and neatness.

- Embossing station is operated lifted up and pulled down freely. During operation, this will provide more choices for both thick sheet and thin sheet and to upgrade product quality.

- Sheet thickness control uses screw and pressing roller two-way adjustment, this may control the sheet thickness precisely.

- Sheet length is control by PLC and driving by servo motor to get accurate size.

- Electric control box: it completely uses high class and qualified accessories and it is of save space design, operation for that is simple and convenient.

P.P. Sheet Extrusion Line

MGB-PPS-Serial

Features

Gallery

Specifications

swipe your finger

| Model | MGB-PPS-Serial |

|

Applicable resin |

P.P. |

| Effective width | 900 or 1,100 or 1,200 mm |

| Thickness range | 0.3 - 1.5 mm |

| Output | 60 - 250 kg/hr |

| Required power | 160 kw |

| Actual power consumption | 85 kw |

| Optional equipment |

(1) 20 ton chiller : 1 (2) 300 kg mixer with drier system : 1 (3) Auto. Dosing blender : 1 (4) 56/56 gear pump : 1 (5) Twin shaft non-stop screen changer : 1 (6) Film winder : 1 (7) Corona treatment : 1 (8) Embossing cylinder : 1 pc |

| Remarks | As we continuously keep working on research and improvement, we preserve the right to change all of the specifications, design and characteristics on this catalogue without notice. |