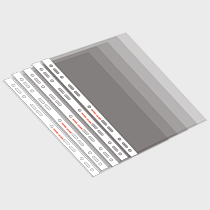

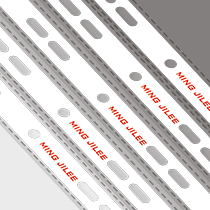

The Ming Jilee Twin Line Sheet Protector Data Bag Machine is an automated system for producing sheet protectors from materials like CPP or IPP. It allows independent or simultaneous operation, with features such as precise punching molds, heat sealing, and cutting systems to ensure uniform bag sizes and minimal waste. Advanced control systems maintain material stability and protect the machine during operation.

- This machine is designed especially for all kinds of data bag (sheet protector) from the plastic feed material (CPP or IPP) to the finished product. The twin line machine can be operated in two ways: one or the other line machine can be operated independently or they can both be operated simultaneously.

- Manufacturing of the bag is fully automatic: the triangle folding device of the machine can run on either single layer film or double layer film; the Electronic Edge Position Controller maintains a uniform position for the feed material; the auto tension control maintains the stability of the feed material during the manufacturing process. Each functional aspect of the machine is essential to the stability of the manufacturing process, not only save labor costs, but also raise productivity.

- This machine is equipped with various precision and durable punching molds with a very low breakdown rate, connecting to the servo motor and digital computing unit for length control to allow a very precise punching position.

- This machine is equipped with a heat sealing device and twin blade cutting device (with a stationary lower blade and a guillotine-action upper blade) which ensure the size of the bags are uniform. The sealing line is neat and elegant and the waste ratio is reduced to a minimum.

- In order to reduce the impact pressure on the heat sealing device and to ensure a consis- tently smooth seal, the surface of the feed tray consists of a soft, silicon-based material.

- This machine is equipped with high quality, high performance parts to incorporate all kinds of control and monitor systems. During operation, anything unusual will automatically stop the machine in alarm to avoid waste material and protect the machine.