- MING JILEE zipper bag making machine is the special design, which we upgrade the universal side sealing machine with the in line zipper strip hot lamination system.

- The buyer prepares the normal PE, CPP, IPP, BOPP, EVA material and zipper strip material, then you can produce the zipper bag product.

- MING JILEE designs the extra tension controller system to feed the zipper strip material to main side sealing machine. With this design, the buyer can get very high quality of the zipper bag from MING JILEE zipper bag making machine.

- Ultra-MING is the special ultrasonic system which design and manufacture by MING JILEE group to get very strong zipper strip fixed on the bag.

- For the customized item, we can put Holes punching, auto slider inserting system, In-line barcode system.

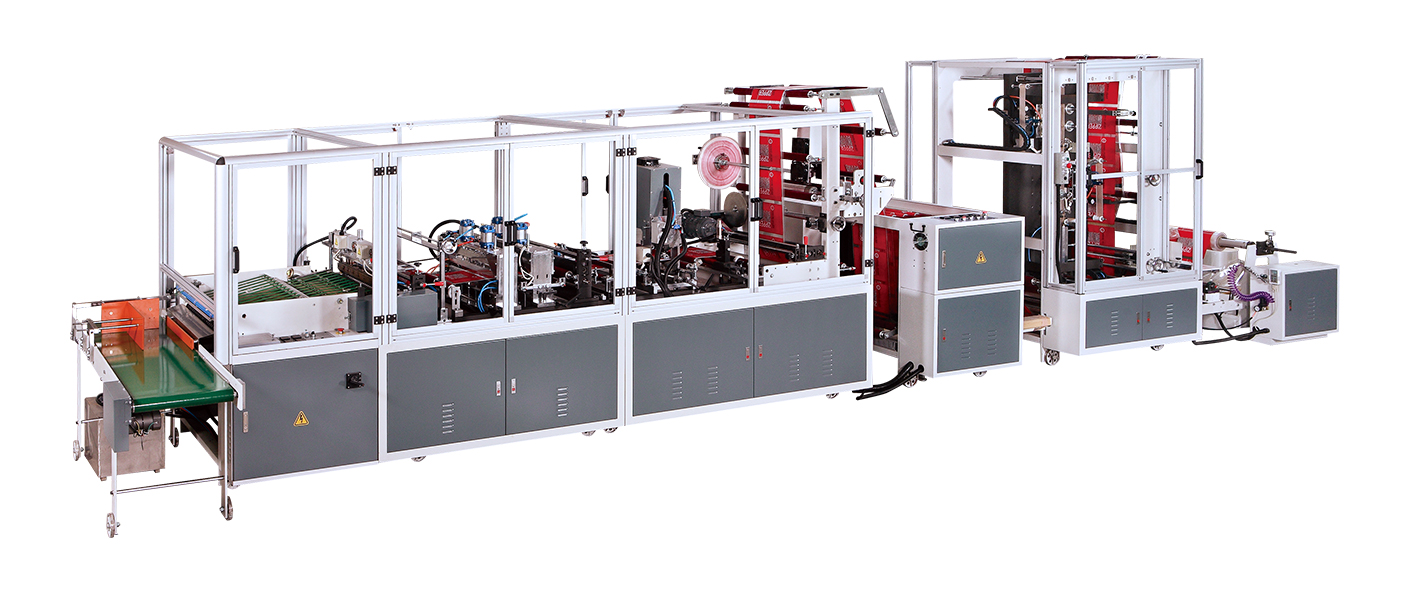

Zipper Bag Making Machine

MGA-06Z-700A

Features

Specifications

swipe your finger

| Model | MGA-06Z-700A | |

|

Feed material |

CPP (pre-folding) , IPP, PE | |

| Effective cutting width (feeding length) | 75 - 600 mm | |

| Effective cutting length | 600 mm | |

| Single layer film thickness |

(1) Side sealing bag : 0.015 - 0.1 mm (2) Zipper bag : 0.04 - 0.1 mm |

|

| Output |

(1) Side sealing bag

(depend on the thickness and length size) : 40 - 200 pcs /min (2) Zipper : 40 - 60 pcs /min (Depend on the thickness of film) |

|

| Machine dimension | 9,000 (L) x 2,000 (W) x 2,200 (H) mm | |

| Required power | 8 kw | |

| Optional equipment |

(1) Auto. conveyor with counter : 1 (2) Hanging bag system : 1 (3) Triangle folding unit : 1 (4) 3′′ air shaft of unwinding : 1 |

|

| Remarks | As we continuously keep working on research and improvement, we preserve the right to change all of the specifications, design and characteristics on this catalogue without notice. | |